Description

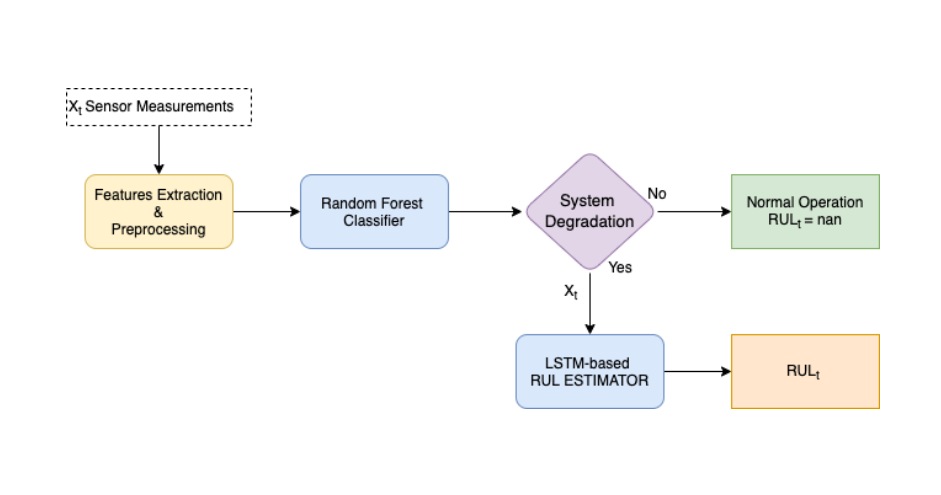

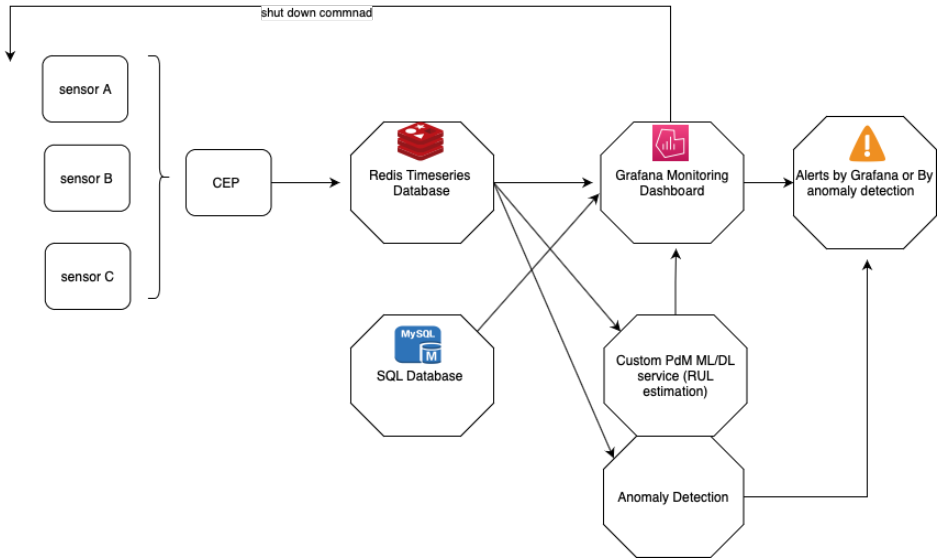

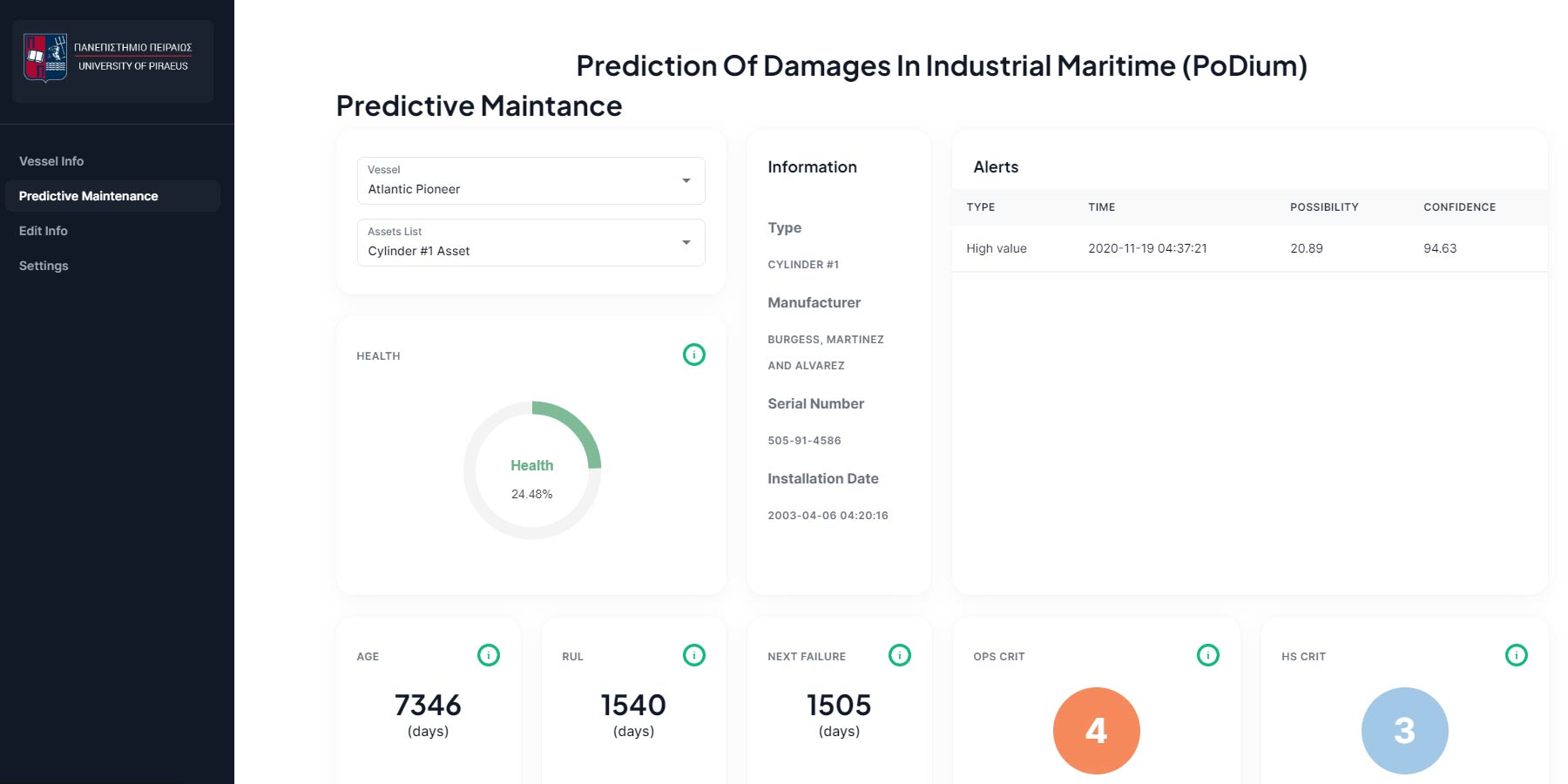

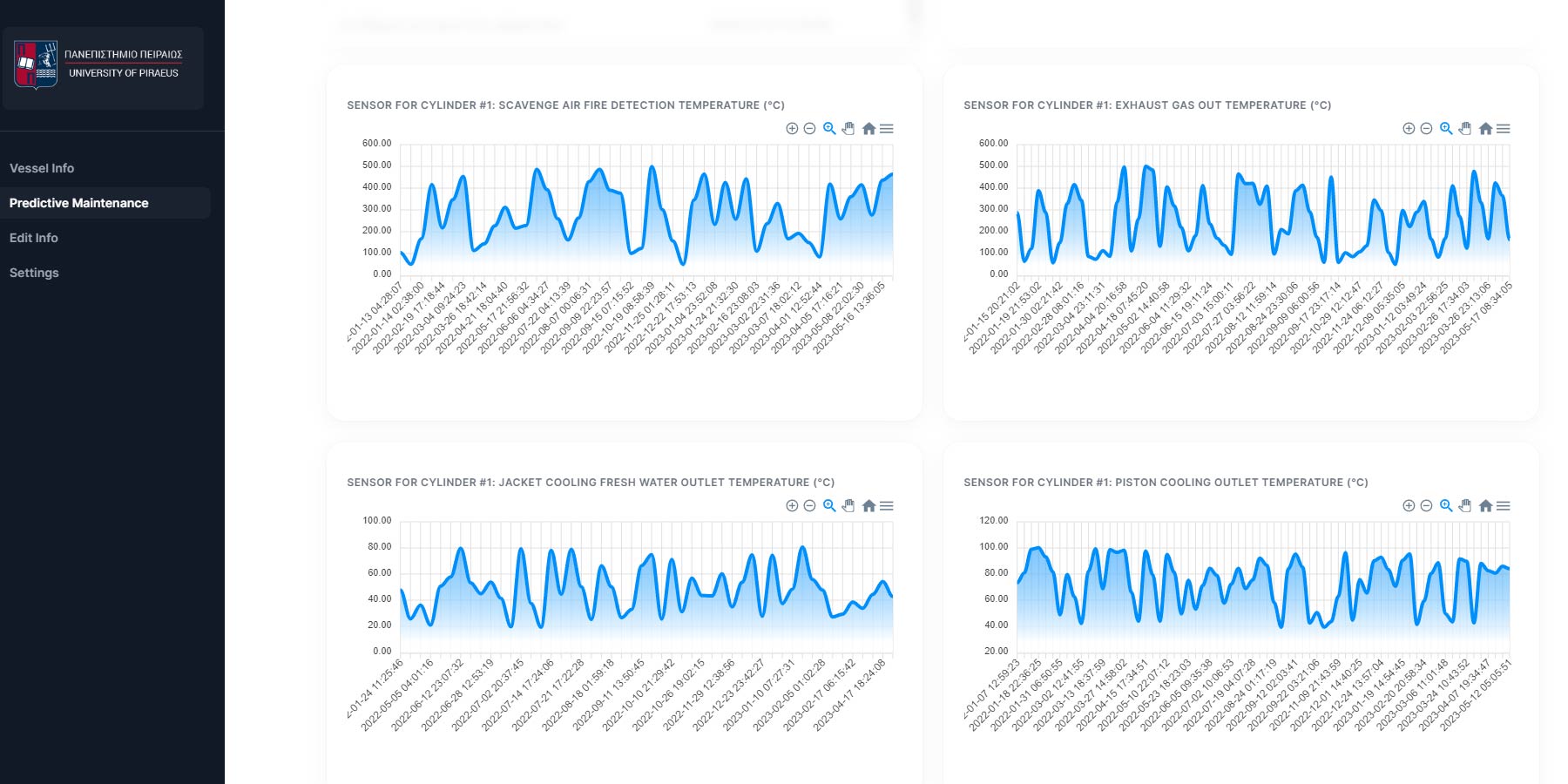

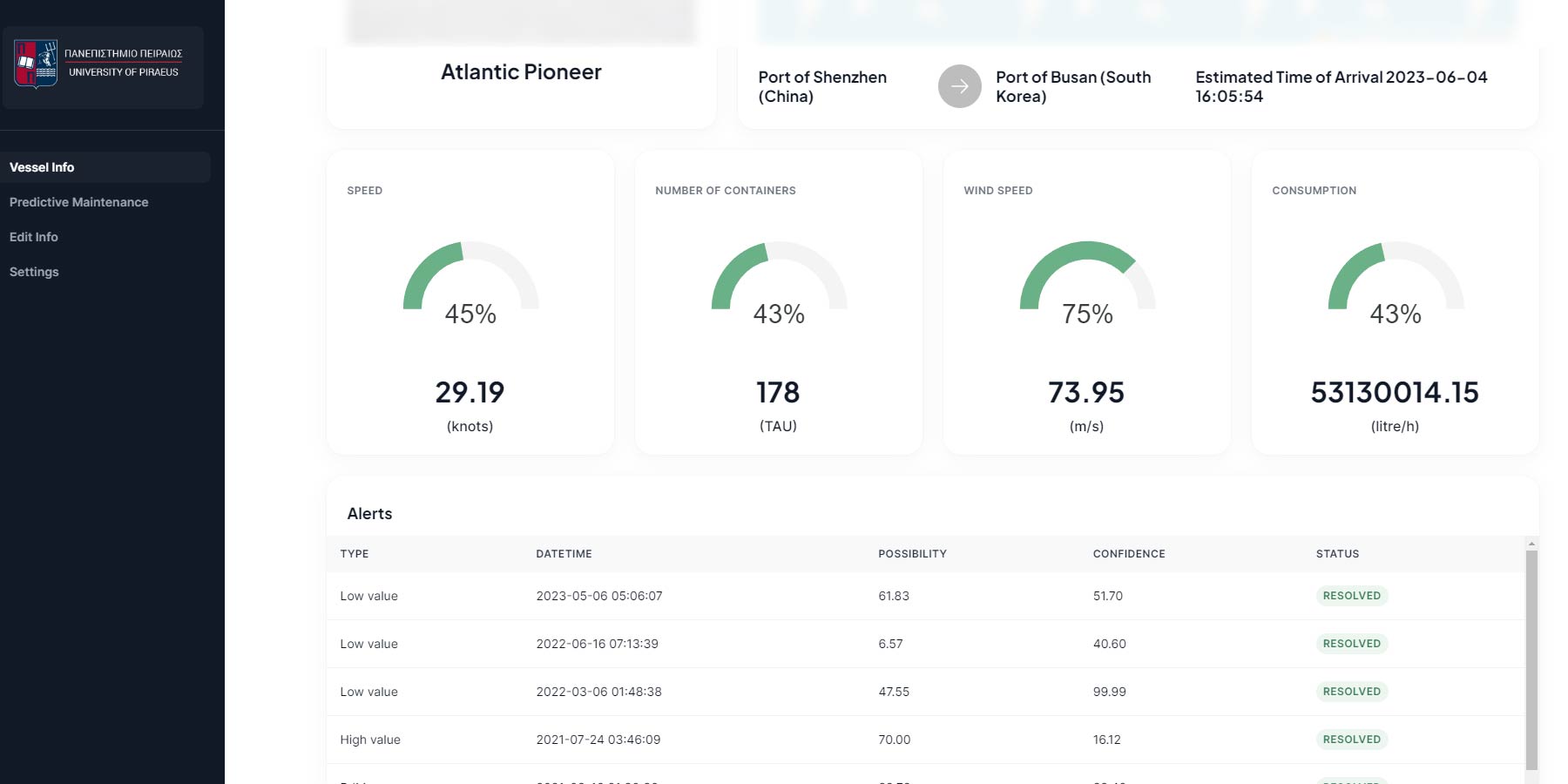

Most shipowners already have or intend to equip their fleet vessels with sensors to collect data concerning both the overall condition of the fleet and the operating condition of the equipment and mechanical parts of the vessels. The proposed tool will aim at the analysis of data flows (collected by sensors) in real time with innovative approaches and artificial intelligence techniques, aiming at the prediction, timely and accurate diagnosis of possible errors in the mechanical equipment (with emphasis on engines) of ships.

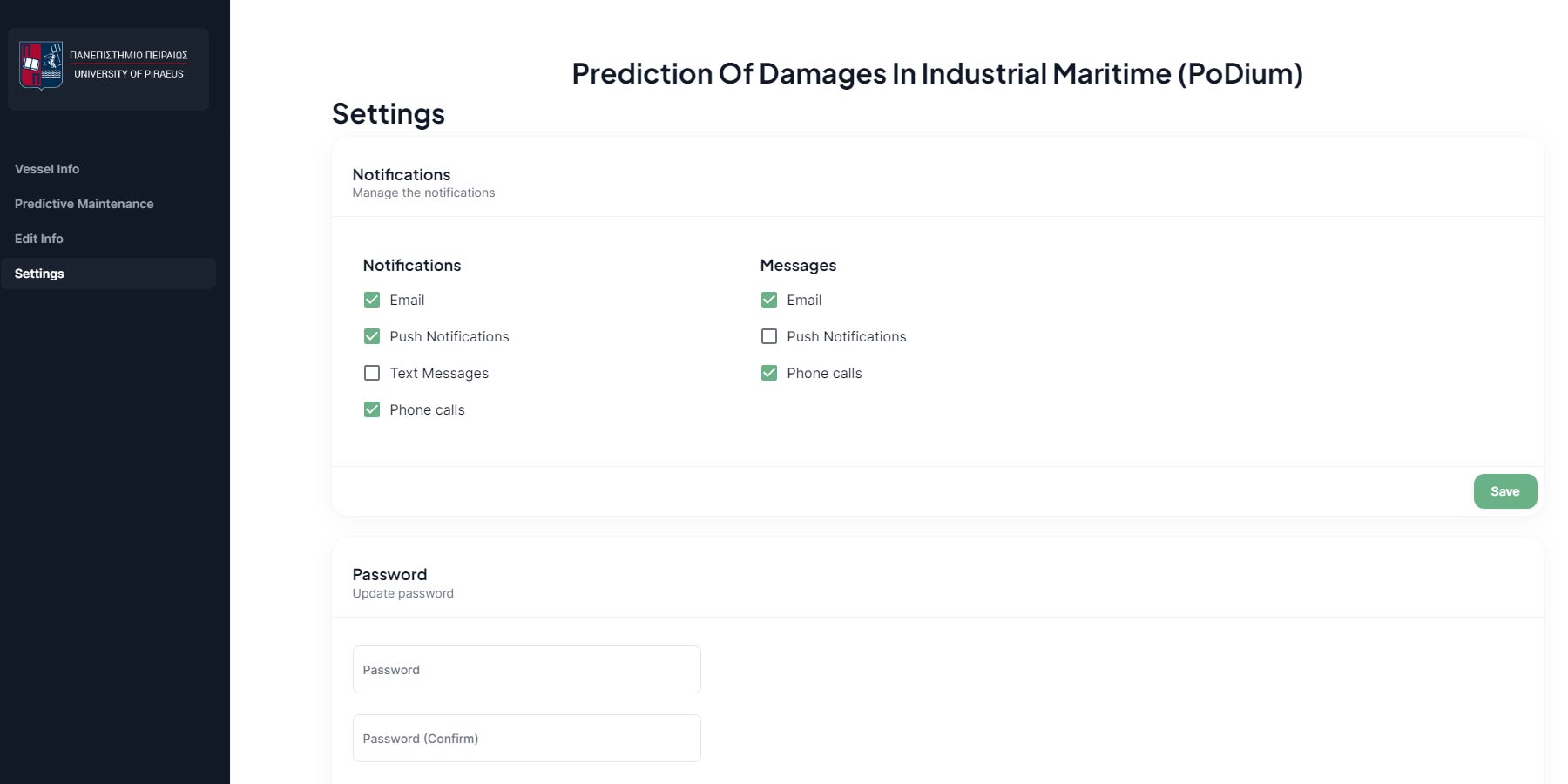

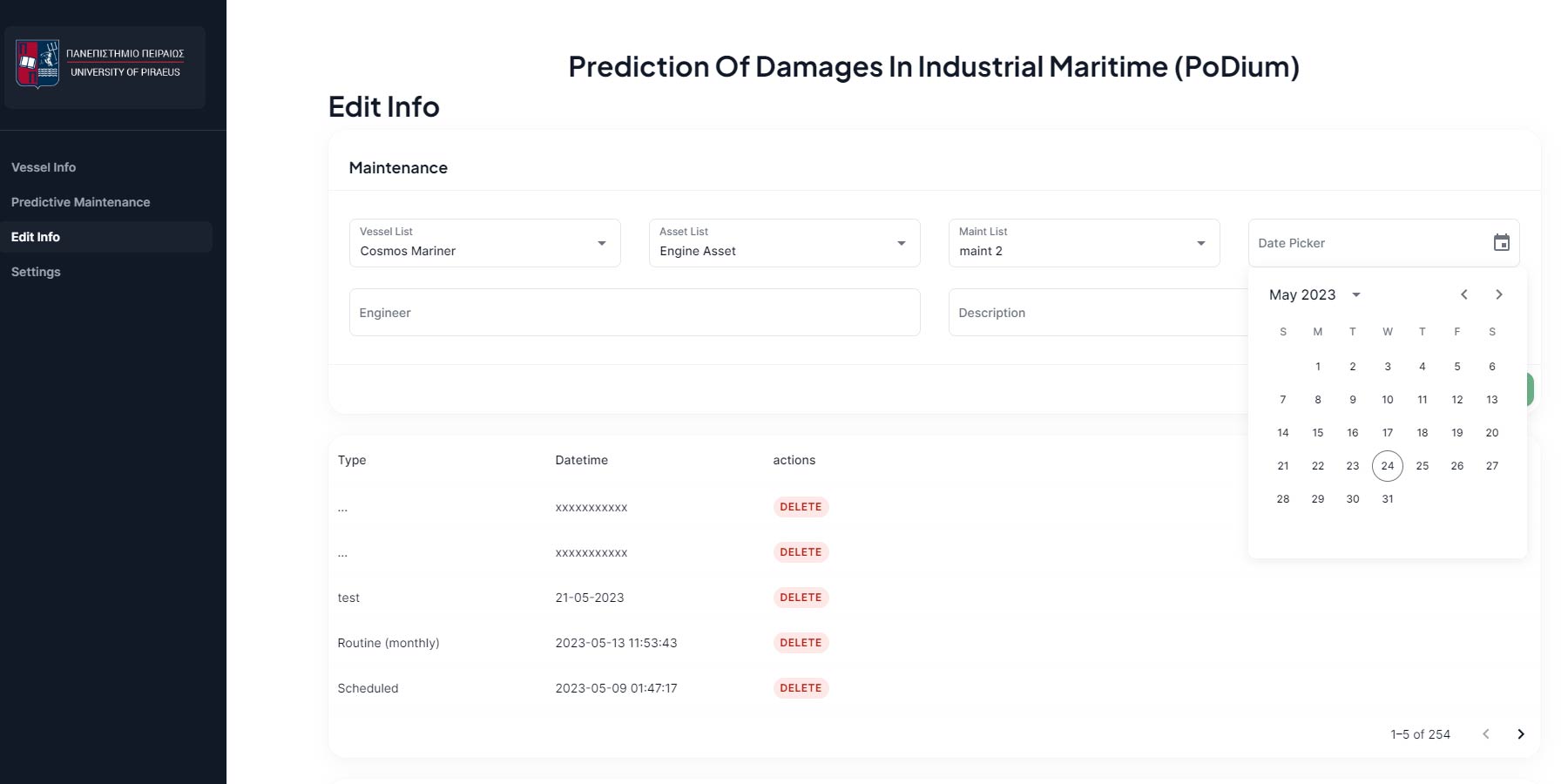

Specifically, PoDiuM aims to optimize decision-making regarding the maintenance of ship engine components through early warning in the event of a failure, the ordering of spare parts or the re-routing of the ship to ports to replace components in the event of early failure.

The sensors that will be installed on the ships (and especially on the engines) will provide information regarding the temperature, pressure and vibrations in various parts of the main engine. This information, in combination with general data such as power consumption, main shaft speed, main shaft torque, will help to detect possible mechanical failure in the early stages.

This means that the shipping company will be able to effectively manage the immediate defect / damage. In this context, the technologies based on PoDiuM will be state-of-the-art engineering and deep learning technologies, creating an integrated information system that will predict possible damage to mechanical parts of the ship.

Ελληνικά

Ελληνικά